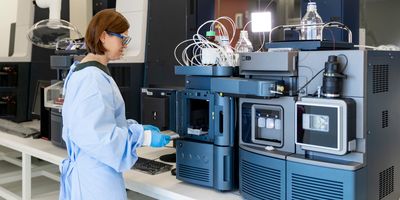

Exploring the Future of QA/QC Labs

Discussing AI, automation, sustainability, and new product developments with Fraser McLeod from Waters Corp

During the 2024 Pittcon Conference & Expo, Reece Alvarez (RA) and Scott Hanton (SH) from Lab Manager had the opportunity to speak with Fraser McLeod (FM), vice president, general manager, QA/QC and Wyatt Technology, from Waters Corporation. We were very interested in Fraser’s perspective on global QA/QC labs and on the integration of Wyatt’s light scattering technology with the broader Waters portfolio after the acquisition.

SH: What's new for QA/QC labs from the Waters-Wyatt combination?

FM: We announced yesterday a new software product called HPLC CONNECTTM 4.0. Now, users of Wyatt software can fully run a Waters LC plus a Wyatt detector in a seamless manner. This is a way for the two products to work seamlessly together. The Wyatt Astra software is still required. The new product is a plugin that enables control of the instrument.

SH: Do you think that as Waters and Wyatt further integrate their operations, that Astra is going to go away? Is it all going to be Empower someday?

FM: We have no immediate plans to replace Astra. We have a large installation base, and a lot of customers are very happy with it. The most common requests we get from our customers after the acquisition are when will Empower support be added. And that's why we're working on it.

SH: Our audience is very interested in AI. Can you help them navigate that space? There are two big areas of interest. One is to help labs process data better—their own and internet resources. The other is to use experimental information to help improve experiments.

FM: The way we try to think about it is to start with a problem, not the technology. Because you don't always need AI or ML to solve the problems. Now, it doesn't mean that we can’t do more and leverage the AI technology to do better. We will have AI and ML coming. But we'll always start with a customer problem first.

SH: Another thing that our readers are asking us about is sustainability. How are Waters and Wyatt working to help labs improve their sustainability?

FM: Waters has done a lot. We have an ESG report that talks about reducing our overall carbon footprint by reducing greenhouse gas emissions and waste. For individual scientists, we’ve continued innovations to tackle sustainability. Our new triple quad – the Xevo TQ Absolute, for example, has earned the prestigious ACT Label from My Green Lab, which helps our customers make an environmentally conscious choice without having to sacrifice analytical performance and results. . We're proud of where we've gone, [and] obviously, we will keep doing more.

SH: Is there anything that vendors can do to improve the sustainability of packaging?

FM: One of our stated claims at a corporate level is to reduce packaging waste overall. The area we've had the most recent impact is on our column packaging. We ship many more LC columns than we ship instruments, and we are now at a point where our column boxes are one-third the size they used to be and are 100 percent recyclable.

SH: How are you thinking about automation in labs?

FM: Every business in the world wants to improve productivity and minimize errors. How do you minimize errors in a lab? Clearly automation has a large part to play. We've introduced a portal to LCs called the automation portal. It's an open portal, which means that any sample prep device can feed our instruments. The automation portal allows any robot arm to pick the tray up [and] put it on the portal. The portal will not just recognize the tray, it will carry all the information about what's in the tray. The analysis starts automatically.

RA: When you envision the frontiers of science that you're involved with five to 10 years out, what do you envision? Where are things going?

FM: It's hard to predict. The field of drug development and discovery is always rapidly evolving. But it's maybe even more rapidly evolving right now. First it was small molecules, then it was mAbs, but now it's a whole plethora of different treatment modalities. And, unfortunately, as we all know, there's new diseases that spring up. What I'm comfortable in saying is, wherever the industry goes it typically anchors around a few fundamentals. Can I understand the molecule the way I need to understand the molecule? Can I do that in the easiest, most time-efficient way possible? And can I do that to the highest level of data integrity that the regulators need?

SH: We think of drug discovery now as one molecule that can serve a billion people. But I think we're heading for one to one; I think we're heading for personalized medicine. And that means multiplying the number of analyses by a billion.

FM: That's a good way to think about it.

SH: How does the technology scale? Technology cannot be the reason why personalized medicine doesn't work. It becomes both a hardware problem of how do you get enough samples to the instrument, but even more so it's a software problem of how do you track that data and metadata perfectly accurately? Because if it gets crossed, then the wrong person is going to get the medicine.

FM: So, there's a lot of big questions that come from that. But any time a challenge like that has been put in front of our innovation teams, they've been able to find a solution— any regulatory challenge, any throughput challenge, or anything like that. We’ve just got to keep our finger on the pulse all the time.